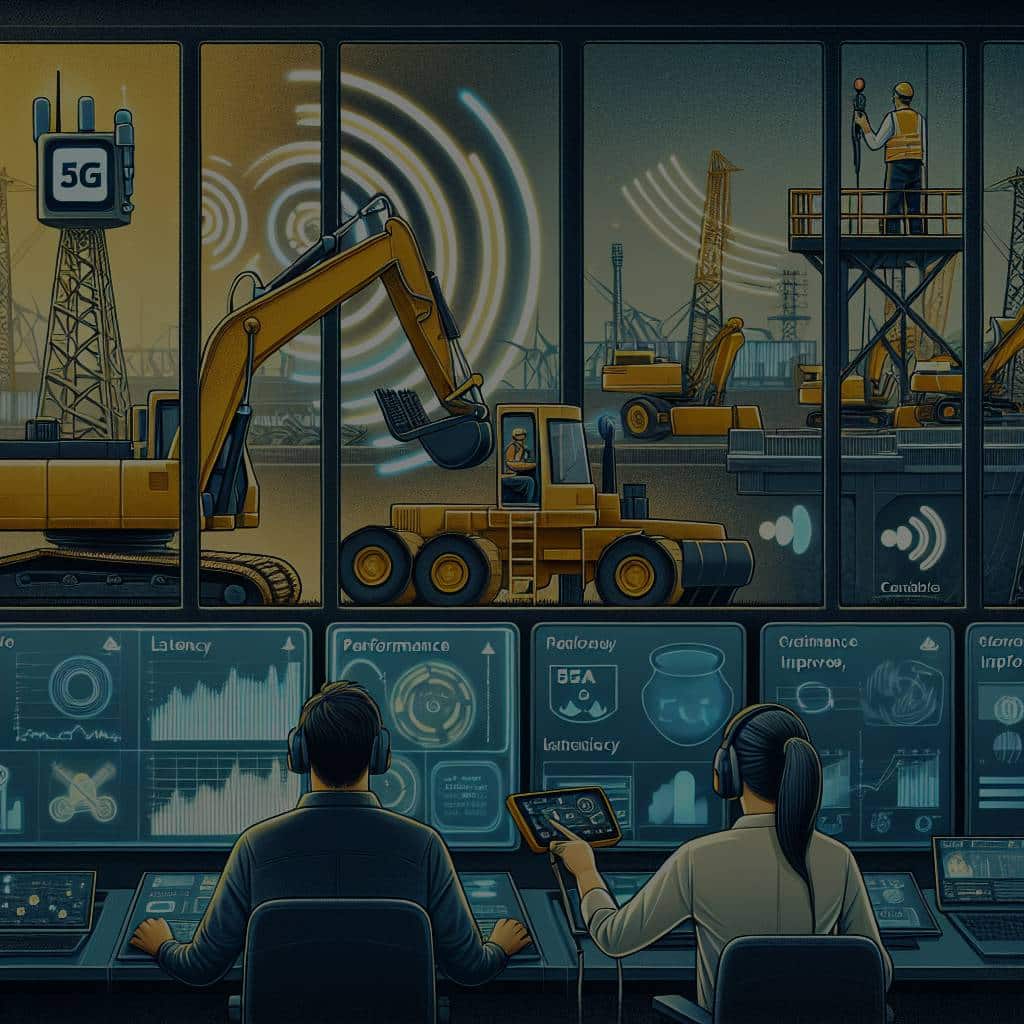

As you navigate the rapidly transforming landscape of the construction industry, you may find yourself frequently encountering terms like ‘5G’, ‘IoT’, ‘remote control’, and ‘heavy machinery.’ These buzzwords are not mere industry jargon. They are, in fact, integral components of a growing trend that is reshaping the face of construction management and operations. More than ever before, technology is weaving itself into every aspect of construction, revolutionizing processes, and paving the way for unprecedented efficiency, safety, and productivity.

5G and Its Implications for the Construction Industry

Before we delve into the impact of 5G on the remote control of heavy machinery, it’s essential to understand precisely what 5G is and why it’s worth your attention. 5G, or the fifth generation of wireless networking technology, is a leap from its predecessor, 4G. It promises faster data speeds, more reliable connectivity, and significantly lower latency.

Have you seen this : How Can Smart Glasses Transform the Efficiency of Field Service Technicians?

In layman’s terms, imagine trying to control a piece of heavy machinery remotely. With 4G, there may be a slight lag between your command and the machine’s response. However, with 5G, the machine would react almost instantaneously to your command, thanks to the reduced latency and faster data transmission. Such real-time control is invaluable in the construction industry, where precision and timing can significantly impact productivity and safety.

Harnessing 5G for Remote Control of Heavy Machinery

Technology has always played a vital role in the construction industry. Still, it is the advent of 5G that has truly accelerated the adoption of remote control solutions for heavy machinery. By leveraging the superior connectivity and data speeds offered by 5G networks, construction firms can now control their heavy equipment remotely in real-time.

Additional reading : How Is AI Being Used to Optimize Urban Waste Collection Routes?

Such control is not limited to simple operations. With sophisticated software applications and the power of 5G, you can operate complex machinery such as excavators, cranes, and bulldozers from a remote site, with the same precision and responsiveness as if you were physically present.

This shift to remote control has several advantages. It can eliminate the need for operators to be on-site, reducing potential safety hazards. Additionally, it enables construction firms to recruit talent from a broader pool, as operators no longer need to be physically present at the construction site.

The Role of IoT in Remote Control of Heavy Machinery

As we discuss 5G and remote control of heavy machinery, we cannot overlook the crucial role of the Internet of Things (IoT). IoT essentially involves connecting various devices and machinery over a network, enabling them to collect, share, and analyze data.

In the context of construction, IoT can provide real-time data about the performance and health of your heavy machinery. You can monitor fuel consumption, identify maintenance needs before they become critical, or even predict potential equipment failures.

5G networks provide the high-speed connectivity required to transmit this vast amount of data in real time. Leveraging IoT and 5G together, construction firms can create a network of interconnected machinery, all controlled and monitored remotely.

Future Prospects: 5G, IoT, and Construction

While the impact of 5G and IoT on remote control of heavy machinery in construction has been substantial, it is just the tip of the iceberg. As 5G networks continue to expand and mature, their potential applications within the construction industry are vast and varied.

For instance, imagine a future where drones equipped with high-definition cameras conduct site inspections, sending back real-time video feeds over 5G networks. Or consider the prospects of augmented reality (AR) and virtual reality (VR) in construction – from training operators to providing virtual walkthroughs of construction sites, all made possible by the low-latency, high-speed data transmission of 5G.

The advent of 5G is undoubtedly a game-changer for the construction industry. It empowers you to leverage the power of remote control and IoT, enhancing safety, efficiency, and productivity. As you navigate this exciting new frontier, remember that embracing technology is not just about staying ahead – it’s about building a safer, more efficient, and more sustainable future for the construction industry.

Integration of Artificial Intelligence in Remote Control of Heavy Machinery

Embracing the advent of 5G and IoT, the construction industry is now setting its eyes on another transformative technology: Artificial Intelligence (AI). AI has the potential to greatly enhance the remote control of heavy machinery, making operations more efficient and precise.

AI can be integrated into the remote operation of construction equipment in several ways. One prominent application is the automation of repetitive tasks. By using AI algorithms, tasks such as digging, drilling, or materials transportation can be automated, freeing up human operators for more complex tasks. This not only increases efficiency but also reduces potential human errors and safety hazards.

AI can also play a crucial role in decision-making processes. Using real-time data collected by IoT devices and transmitted over 5G networks, AI algorithms can analyze patterns, predict potential issues, and make optimisations. For instance, AI can predict when construction machinery is likely to require maintenance, enabling companies to schedule servicing in advance and avoid unexpected breakdowns.

Furthermore, AI can augment remote control by providing operators with valuable insights. For instance, using AI-powered analysis of real-time data, operators can receive alerts about potential safety hazards or efficiency bottlenecks. This information can enhance decision making, leading to safer and more productive construction sites.

Lastly, AI facilitates the implementation of edge computing in construction. Edge computing involves processing data close to the source, reducing the need for data transmission and thus lowering latency. With AI, construction companies can process vast amounts of real-time data on-site, enhancing the responsiveness and precision of remote control operations.

As per various studies on Google Scholar, the integration of AI with 5G and IoT in remote control of construction equipment could bring about a new era of smart construction, enhancing efficiency, safety, and decision making.

Conclusion: Building a Smarter Future for the Construction Industry

The construction industry stands on the brink of a revolutionary change, powered by the advent of 5G networks and IoT connectivity. The remote operation of heavy machinery, enabled by this technological synergy, promises to bring about unprecedented levels of efficiency, safety, and productivity in construction processes.

The implications of this shift are profound. Not only does it reshape the way construction companies operate their equipment, but it also has the potential to redefine the very nature of construction sites. With operators able to work remotely, and AI providing intelligent insights, construction sites can become safer and more efficient.

Further integration of Artificial Intelligence and edge computing will enhance these benefits, providing real-time analytics and facilitating more effective decision-making processes. The role of AI in automating repetitive tasks and offering predictive maintenance can significantly increase construction equipment’s operational time and reduce costs.

As we move towards a future of interconnected machinery, drones, and virtual reality applications, the construction sector is set to become more technologically advanced, bolstered by the power of 5G, IoT, and AI. This is not just about staying competitive—it’s about paving the way for a safer, smarter, and more efficient construction industry.